Month: November 2014

University-based dairy enterprise makes waves in Caraga Region

Some 300 kilometers from the Philippine Carabao Center at Central Mindanao University (PCC at CMU) in Musuan, Bukidnon another carabao-based enterprise is thriving in the Caraga Region.

The dairy enterprise is a product of PCC at CMU’s partnership with the Caraga State University (Car.SU) in Butuan City. The tie-up took effect in 2000 when Car.SU became a beneficiary of PCC at CMU’s 25-cow dairy buffalo module, which is part of PCC’s herd build-up program to propagate high-quality buffaloes that eventually become sources of milk and meat.

Under the program, 25 head of purebred female dairy buffaloes and a junior bull are loaned to interested institutions or cooperatives upon satisfying several requirements. The recipients will then repay PCC through the first calf produced by each cow.

Couple-professors Dr. Emmanuel and Prof. Miriam Nono were tapped by then Car.SU President Wenceslao Tianero to spearhead the project for the university.

“Pres. Tianero adopted the project not only for instructional but also for research, extension, and income generating purposes,” said Dr. Emmanuel, who was then the director of the university’s Income-Generating Project (IGP) and a professor at the university’s College of Agricultural Sciences and Natural Resources, handling animal sciences courses.

His wife was also a professor in the same college, teaching secondary post-harvest processing and quality evaluation.

Even without prior experience in carabao production, the couple accepted the new challenge.

“I didn’t have any doubts when the project was offered to us, knowing that the university would provide us the needed support,” Prof. Miriam said. She added that they were chosen to head the project because their respective expertise needed in carabao production complemented the other.

“My husband is a veterinarian while I am into food processing,” she said.

Preparations were made for the arrival of the dairy buffaloes. In August, 2000, a shed inside the university’s 200-hectare farm was selected to house the buffaloes. A staff was also sent to PCC at CMU to undergo a one-month training on basic carabao production and management, including dairy processing.

The buffaloes arrived in three batches, starting with 11 head in November 2000 and the last in 2002.

Start-up challenges

By early 2001, milk started to flow from the buffaloes. Milk collection amounted to about 10 liters daily. Along with their staff and two other student assistants, they started processing the milk.

Marketing the products consisting of pasteurized fresh milk and choco-milk, however, was a bit of a dilemma. In the first place, students of Car.SU, who were the target market of the project, were not milk drinkers. They also held wrong beliefs that carabao’s milk has adverse effect on the body and it can induce a mother who just gave birth into a coma after taking it.

Enlightenment could only come through proper education. Dr. Emmanuel and Prof. Miriam undertook an informal information campaign, highlighting the nutritional values of carabao’s milk to debunk unfounded beliefs.

“We explained to them that the milk came from non-working buffaloes. We also told them of the nutritional benefits of drinking carabao’s milk,” Prof. Miriam said, adding that they had to make other products, such as ice candy, to make these more enticing to students.

Slowly, by word of mouth, more and more people began patronizing the dairy products. The milk became an advertisement in itself, which led non-milk drinkers to reconsider their beliefs. The number of customers gradually multiplied.

Students started bringing fresh milk as “pasalubong”, small gifts to their parents when they went home to their villages. In a way, the students served as unofficial advertisers of the project’s dairy products.

In June 2001, sales began to pick up, an offshoot of the continuous information campaign.

Awareness doubled when former Congressman Leovigildo Banagaag of the 1st district of Agusan del Norte and former Butuan City Mayor Democrito Plaza sponsored a School Children Milk Feeding Program in 86 barangays in Butuan City and its neighboring town, Las Nieves. The milk feeding program ran from 2002 to 2004.

“We processed twice a day to cope with the demand for the milk feeding and delivered the sachets of choco-milk to elementary and high schools in several remote areas,” Prof. Miriam shared. She added that they would buy milk from PCC at CMU when they ran out of raw milk.

For almost four years, the milk processing and marketing activities took place in the university’s Food Technology Center, which was also managed by Prof. Miriam.

It was in 2004 that a formal processing plant and marketing building was established through a grant from then Agriculture Secretary Leonardo Montemayor, who allocated P500, 000 for the facility. The university augmented the grant with an allocation to complete the facilities.

Further, using the income from the milk feeding program, they were able to acquire cold storage facilities that are needed to maintain milk quality.

In the same year, they were able to complete the animal repayment obligations to PCC at CMU. Since then, male calves produced were sold while female calves were retained for milking.

At present, the Car.Su dairy project maintains 50 cows and a junior bull for natural breeding.

Expanding the “BumBu” product line

With the increasing acceptance of carabao fresh milk in the area, the challenges for the Nono couple also grew. These included the need to improve their products and introduction of new ones through continuous collaboration with PCC at CMU.

Apart from the two original products, pasteurized milk and chocomilk, the couple produced their own versions of pastillas de leche and yogurt, which come in several flavors. They were also able to develop white cheese, which is a hit among local entrepreneurs who are making pizzas and the community of Indian nationals in the area.

All these products are being sold under the “BuMBu” label, a name penned by the couple. It was derived from Bulgarian Murrah Buffalo, the breed of the buffaloes utilized under the project.

Pains, gains

During the initial years of the project, the couple had to dedicate every free time to it.

“We had to extend our duty hours in the project, particularly in the processing and packaging of the dairy products. Usually, we put in two to three hours after office hours to the project and even devoted weekends and holidays without claiming any overtime pay and additional compensation from the university,” Dr. Emmanuel said.

The couple’s sacrifices were more than compensated though as the project is steadily improving through the years.

The original stocks doubled from 25 cows to the current 50. From only 10 liters of total milk collection per day, they are now collecting 20 to 25 liters.

Their market has gone beyond the gates of the campus and is steadily growing. The Car.SU dairy products now reach as far as Manila and even other countries by way of the OFWs who these items when they return for work.

Indian nationals are some of their regular patrons who buy fresh milk early in the morning.

On top of it all, the Nonos are happy with the impact of the project on the community.

“Our customers, especially the students, buy dairy products such as chocomilk instead of soft drinks,” Prof. Miriam related. “This is very important for their nourishment,” she added, agreeing that, in a way, they started the culture of milk drinking in their area.

A passion and an advocacy

The project may relatively be considered established and successful 14 years after its inception. As Prof. Miriam puts it, the enterprise is “progressing.”

Challenges, however, never run out.

Due to the frequent rotational brown out in Butuan City, keeping the products from spoiling becomes a struggle. There were times when they have to throw away spoiled dairy products.

To avoid further losses, the couple would buy large quantities of ice to preserve the products.

The couple would shell out their personal money to keep production going when acquisition of processing materials and ingredients are delayed.

Time and again, the couple has to contend with some intrigues about the project losing. These are easily squelched however by the increase in proceeds and the facilities put up from the sales of the products.

Always striving for improvement, Dr. Emmanuel bared his plans of adding more breeding and production stocks and expanding the processing plant.

He also hopes to develop “more functional, state-of-the-art facilities” and to train “personnel to be able to cater to and serve the needs of interested farmers in the area.”

In 2000 the Car.SU carabao-based dairy enterprise may have started as simply a job assignment for the couple and their colleagues. Today, it has become a passion and an advocacy for them.

Javier, Leyte: Site of PH’s 1st dairy buffalo multiplier farm

The town of Javier in Leyte province, about 73 kilometers south of Tacloban City, now holds the distinction of having the country’s first ever dairy buffalo multiplier farm (DBMF).

In a simple ceremony held November 8 in Sitio Mapula, Zone II of the municipality, Dr. Arnel del Barrio, acting executive director of the Philippine Carabao Center (PCC), formally turned over to JDBMF proponent-operator Michael Javier 50 Italian Murrah heifers that serve as the farm’s nucleus herd.

Present during the occasion, which coincided with the 1st anniversary of the occurrence of Supertyphoon “Yolanda”, were Javier Mayor Leonardo Javier Sr., Dr. Jose Bacusmo, Visayas State University (VSU) president; Dr. Othelo Capuno, VSU vice president for research and extension; Dr. Julius Abela, PCC at VSU center director, Vice Mayor Emma M. Abueva, Regional Director Cynthia Nierras of the Department of Trade and Industry (DTI); and members of the Javier sangguniang bayan.

The JDBMF will be supervised and monitored by PCC at VSU, which covers Region 8 or the Eastern Visayas region.

“This multiplier farm is the newest program of PCC. We at PCC are always willing to collaborate and participate to the development of our program in the department of agriculture. I hope we will still continue this good collaboration and PCC will always help in terms of breeding, technical services, capability building and many more. That is our promise, we will be of help in any way we can. Let’s help this project to prosper for this will be the stepping stone for a bigger project and to create more opportunities like this,“ Del Barrio declared in remarks during the awarding rite.

In his response, Mayor Javier expressed optimism the dairy buffalo multiplier farm will result in economic benefits for his constituents.

“What does this multiplier farm mean to the town? It means, we will have milk so we will have income. We will have organic fertilizers from their manure. We will benefit a lot. I will prove, in front of everybody here, it is not impossible to make farmers rich and we will achieve that. I will remember this day not only because of (super typhoon) ‘Yolanda’ but because this day marks the first time ever in the history of the Philippines that a multiplier farm is installed in a small town like Javier, Leyte,“ he proudly stated.

The PCC’s DBMF program is aimed at improving efficiency in the multiplication and propagation of good quality dairy buffalo genetics that can be utilized in establishing a viable commercial buffalo-based dairy farm. In this manner, buffalo genetic sources may be widely spread and not limited to PCC

Those interested in applying as an operator of a dairy buffalo multiplier farmer must meet specific qualification-requirements that include the following: a recent business permit or mayor’s permit; a co-maker like legal spouse, parents or children with age of not less than 18 years old; dairy production and management capabilities; willing to be trained on the technical aspects of a DBMF; a titled/long-term leased land with developed pasture area; the means to provide for feed and mineral supplementation; available production facility (animal shed, milking parlor, feed storage, animal treatment and isolation area) and equipment; the capacity to provide ad libitum supply of potable water; and must be able to shoulder the cost of transporting the animals from PCC to the DBMF site.

Those who can apply for the DBMF program include farm owners, corporation, company or cooperative that are already engaged in dairy-related activities and livestock production. Applicants will be subjected to evaluation by the PCC DBMF team.

There is a memorandum of agreement (MOA) which should be signed and agreed upon by both parties (PCC and DBMF) indicating also the requirements mentioned above. The contract generally aims to adopt and pursue rural-based development strategies, and recognize the urgency of developing and strengthening the Philippine carabao industry in relevance to the agency’s mandate.

Moreover, it aims to recognize the importance of DBMF as an appropriate strategy in developing buffalo-based dairy enterprises providing viable opportunities that lead to increased income, higher nutritional status and improved general well-being among participating rural farming families.

“The Department of Agriculture has a P10 million budget to support livestock multiplier farms. One important factor also is the forage development so we, the DA, will deliver 10 sacks of Pakchong 1, an imported variety of Napier coming from Thailand, to this province (Leyte),“ Dr. Wilson Cerbito, DA technical director for research and regulations in Eastern Visayas, said.

Meanwhile, Abela, as the first PCC regional center director to supervise and monitor the first dairy buffalo multiplier farm, expressed his gratitude for and readiness to meet the challenges involved in the project.

“Starting this day, you should have massive pasture development. To all farmers, this will serve as challenge to you. I have mixed emotions toward this project, I am glad at the same time grateful because of the undeniable trust that the management gave to me. I am also overwhelmed because this also serves as another challenge to us. We will do our best to make this first chapter of the Javier multiplier farm a success,” he declared.

Dairy buffalo farmers undergo milk quality improvement training

Two batches of selected farmers from the National Impact Zone (NIZ) participated in a milk quality improvement training conducted by the Philippine Carabao Center (PCC) at its National Headquarters and Gene Pool in the Science City of Muñoz, Nueva Ecija on November 3-6.

The participants comprised milk collectors, milk processors and milk quality officers from 50 dairy cooperatives in the NIZ.

The relation of milk quality to animal health, animal nutrition and other aspects of milk production were discussed. The importance of proper milk-handling practices, milk testing and milk delivery to the dairy plant were also tackled.

Mina Abella, officer in charge of the dairy processing and outlet at PCC at Central Luzon State University (PCC at CLSU) and one of the resource persons, pointed out to the trainees that milk handling, particularly in terms of proper hygiene, sanitation and cooling, is essential in producing a quality product. She said that all the key players in the milk supply chain need to constantly observe proper milk handling and establish good and quick delivery systems as well as payment scheme to improve their milk produce and income.

“Quality and collection officers or farmers also have to do milk testing regularly to determine which milk produce meet quality standards and can be processed into various dairy products,” Abella emphasized.

She advised the farmer-participants to establish a standard where the milk will be accepted or rejected based on the results of various milk tests that will be done, such as the organoleptic test, alcohol precipitation test (APT), lactometer test, clot on boiling test and titratable acidity test.

These are easy-to do tests that can be performed by the farmers in a short period of time, she said.

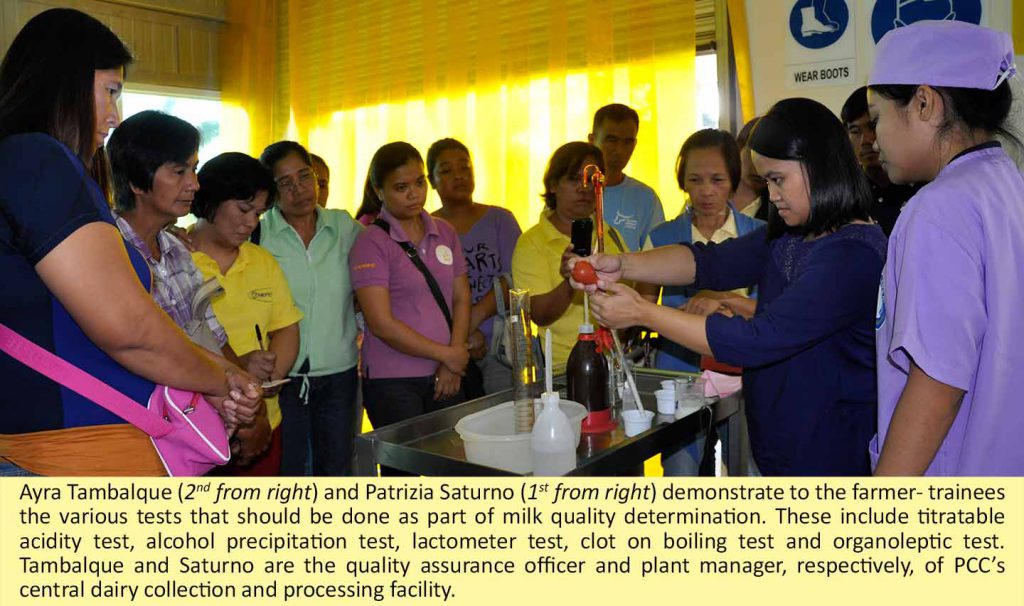

As part of the training, the tests were demonstrated to the trainees by Patrizia Saturno and Ayra Tambalque, plant manager and quality assurance officer of PCC’s central dairy collection and processing facility, respectively.

The other resource persons were Dr. Daniel Aquino, Dr. Lester Verona, Mario Delizo, Wilma T. del Rosario, Marilou Santos, Estella P. Valiente and Jennifer F. Maramba.

Meanwhile, del Rosario, who also served as one of the training facilitators, said that the training is a measure aimed at preparing the farmers for the upcoming summer season.

“Summer season is the time when the dairy farmers attain more milk harvest. However, it is also the time when the temperature is relatively high and milk spoilage can be quite high. Aside from improper milk handling, the high temperature increases the probability of milk spoilage because of the quick reaction of bacteria to the heat,” Del Rosario explained.

“The training is one of our strategies to mitigate the scenario of milk contamination or spoilage due to improper milk handling and increasing temperature,” she added.

Del Rosario said that another batch of dairy farmers will undergo a similar training on November 24-25 .

Meanwhile, for 2015, the PCC, through its dairy herd improvement unit, intends to bring trainings to the farmers’ cooperative level.

“These efforts are part of the PCC’s goal of making Nueva Ecija province the dairy capital of the Philippines,” Del Rosario stated.

PCC at CMU product outlet: A favourite stopover for travellers

One particular spot along the highway in Maramag, Bukidnon, has become a must-stop haven for travellers: the dairy product outlet of the Philippine Carabao Center at Central Mindanao University (PCC at CMU).

In this cozy establishment, they partake of their favourite products and/or take home as “pasalubong” the items of their choice from an array of milk products produced right in the place out of the carabao’s milk harvested in the PCC at CMU farm, just across the highway near the foot of Mt. Musuan.

The available products include fresh milk, choco milk, pastillas (milk candies), white cheese, flavored milk and milk bars. The customers are usually travellers from the towns and cities to and from Davao City and Cagayan de Oro City. And, there too are buyers, not only from Maramag town itself but also from neighboring communities.

In the years prior to 1996, however, things were quite different. In the first place, residents in Maramag and surrounding areas didn’t have a penchant for carabao’s milk.

The existing native carabaos were only used for their draft capabilities. Only a handful of farmer-owners regularly milked their animal either for use as raw milk for food or for making milk products.

The entry of the Philippine Carabao Center at the Central Mindanao University (PCC at CMU) set the wheels of change moving.

Facing challenges in the early years

The PCC at CMU had its first stock of dairy buffaloes when 115 animals consisting of crossbreds and purebreds were consigned to its farm

In the mid-90s, 464 purebred dairy buffaloes were added to the center’s herd.

With limited staff and finances to begin with, Rosenio Anacleto, the center’s first director, was confronted with wracking problems. Undaunted, he faced all these challenges head-on.

Among the initiatives that paid off were appropriate corrals for the animals and pasture areas for the nutritional requirements of the animals.

Soon, the calves started coming in. Milk collection was eventually done, with the center making its mark as a pioneer in milk collection among the PCC’s regional centers in the Mindanao cluster.

The selling of raw milk, however, was a different matter, which took on the nature of a particularly challenging venture.

Processing for value-adding

“Sir Anacleto encouraged us to process the milk collected from the herd. It was a trial and error process. For two days, we conducted trials in processing the milk into choco milk but they resulted in failures. But then, we went on with the needed adjustments until we were able to come out with our initial bottles of the choco milk with the right mix,” PCC at CMU supervising science research specialist Thelma Bagongon said.

She and two other staff members, science research specialist Gina G. Villamor and science research analyst Mary Fe L. Montaño, moved on to commercial production of their own brand of choco milk.

Aside from choco milk, they also perfected the production of other products like pasteurized milk and “pastillas” (milk candy). They carried out the processing activities in the morning and continued to attend to their office works in the afternoon.

Anacleto, who has already retired from public service, decided to use the waiting shed along the highway as their temporary outlet, heralded by the signage “Processed milk sold here”.

Passers-by from different places began noticing the outlet. The hard work of the staff paid off. They were able to generate a monthly income of about Php400,000 from the sales of the products, which they remitted to the PCC main office.

Former PCC executive director Libertado C. Cruz, informed of what the PCC at CMU had done, expressed amazement at the feat.

“Dr. Cruz constantly encouraged Sir Anacleto that he should keep on processing and selling the milk as a way of educating people on the benefits they can derive in drinking buffalo’s milk and partaking of the milk products. He said that many people were on held the common belief that the carabao is only suitable for farm works and not a good source of abundant milk,” Bagongon recalled.

In 2002, the temporary outlet was vacated in favor of a modest building for the selling of the products. This outlet was eventually renovated to keep pace with the growing number of customers.

Now, under the current leadership of center director Lowell Paraguas, the PCC at CMU refined and improved its product line through the acquisition of new processing equipment aided by appropriate research and development.

Science Research Assistant Elena S. Paraguas currently serves as the center’s product development officer. She is assisted by two staff members. Together, they meticulously observe the processing and packaging procedures involved in coming up with the center’s dairy products.

“We are collecting about 240 liters of milk from twice-a-day milking of our herd. Sixty percent of the volume is used for processing and the rest, for feeding the newly-born calves,” Paraguas said.

“We are developing our products based on the need of the market. We also tap the expertise of other PCC product outlets in improving the quality of our products.” Paraguas stated.

He said their center has acquired additional equipment which can help boost the saleability of their products and in developing new ones.

“We worked hard to make this venture a big reality. We have an established business now, earning more than what we have expected before. The initiative of Sir Anacleto has paid off and we will make sure that it is kept going for years to come,” Villamor added.